Rated LTL / Local Carrier Package

|

Includes the ability to rate Ground shipments via LTL for a virtually unlimited number of local and nationwide carriers. Also included are pro number generation, freight collect and third party billing, and three types of Bills of Lading (pdf, laser printer and multi-part forms).

* Label printing requires a thermal label printer supported by PSS.

* The terms box and package are synonymous with the term "pallet" when they appear below.

|

Included Software and Features:

Part # 10004 - Non-Rated Carriers. Create local carriers and enter freight charges

This gives you the ability to create an unlimited number of non-rated local carriers. Freight charges for a given shipment can be entered in the PSS Rating Station and then updated to your database. |

|

Part # 10113 - Hazardous Materials library and multi-part IATA form

In order to identify packages containing hazardous materials, this allows you to create and maintain a library of hazardous codes and then assign the codes to packages containing these items. An approved multi-part Hazardous Materials IATA form is printed on your dot-matrix printer, and a user-modifiable program is provided to print a custom hazardous label when needed.

* Licensee will assume all responsibility and SCI will assume no responsibility for using this feature. |

|

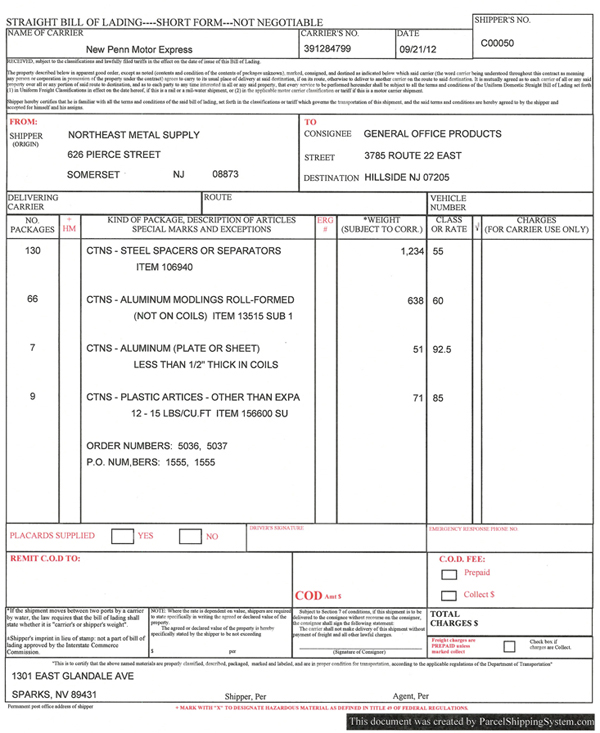

Part # 10019 - Multi-Part Bill of Lading. Designed for use with multi-part standard forms

You can have PSS print your bill-of-lading forms instead of having them typed manually. The user modifiable print program assumes that there is one NMFC code per pallet, is set to print on a standard Rapid Forms bill-of-lading, and can easily be modified to print on your forms. The print program will also create a consolidated Bill of Lading if the Box Consolidation Option is licensed.

|

|

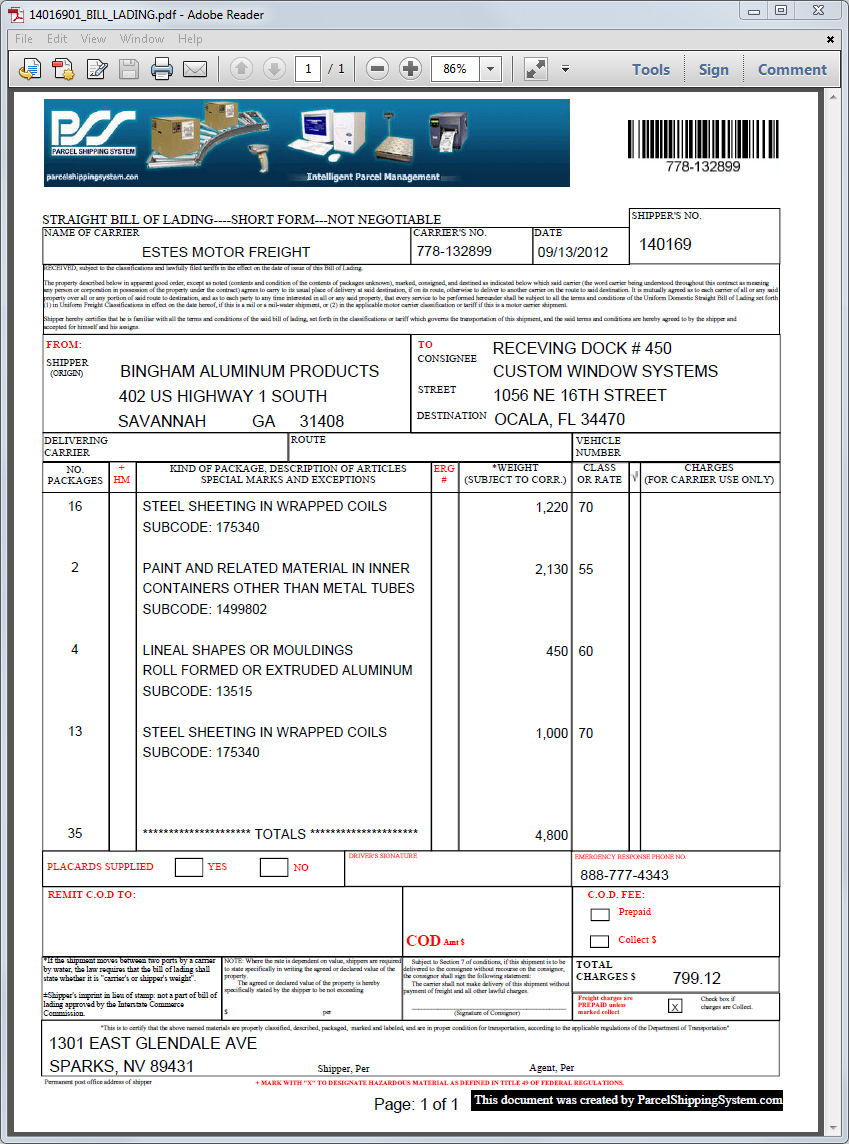

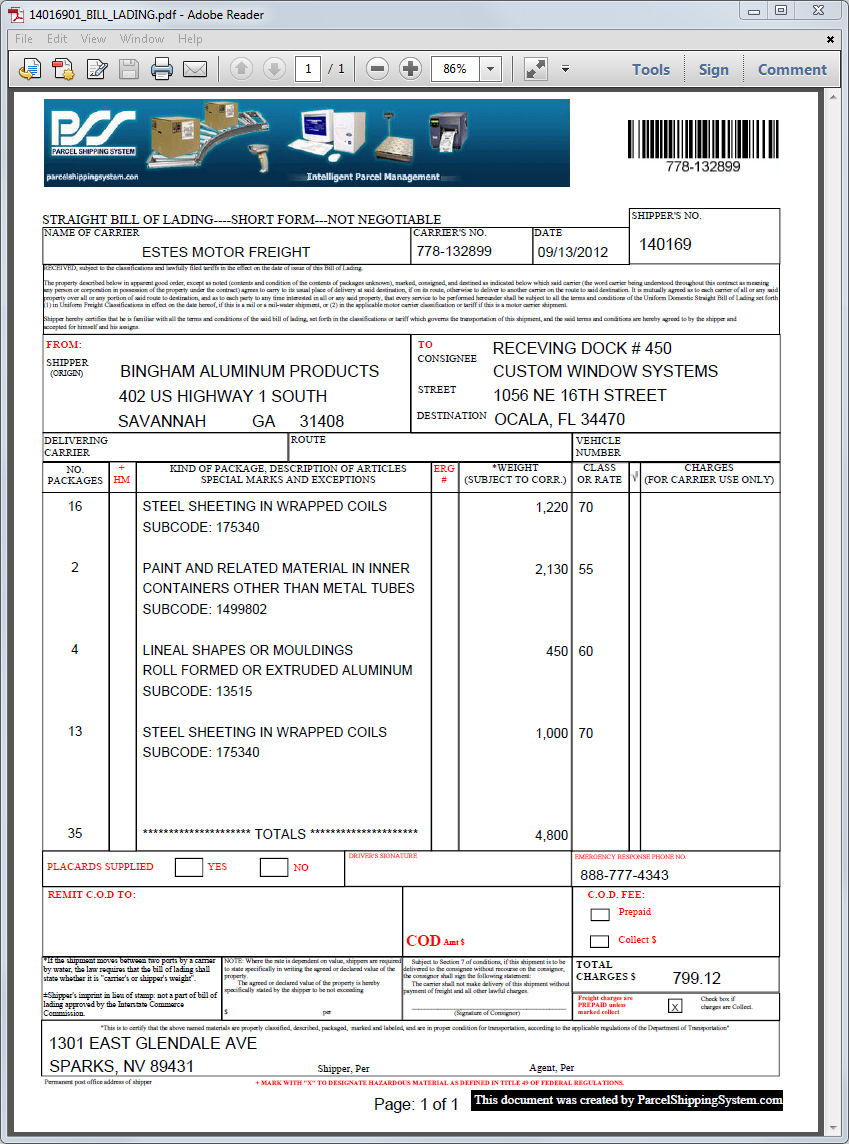

Part # 10117 - Bill of Lading Form - PDF

This will create Bill of Lading in pdf format. It will also create a consolidated Bill of Lading if the Box Consolidation Option is licensed. The program will print a dynamic, personalized company banner which can be used simply as a logo or as a tool to introduce new products to your customers. The print program is user modifiable, and the resulting electronic document may be printed, archived, or included as an attachment when using our advanced email option.

Notes that apply to all forms:

* Samples of all package forms are available on our web site.

* Level II interface customization is requred and will be done on a T&M basis.

* Design, Installation, training, etc. will be done on a T&M basis.

* All forms can be customized on a T&M basis. |

|

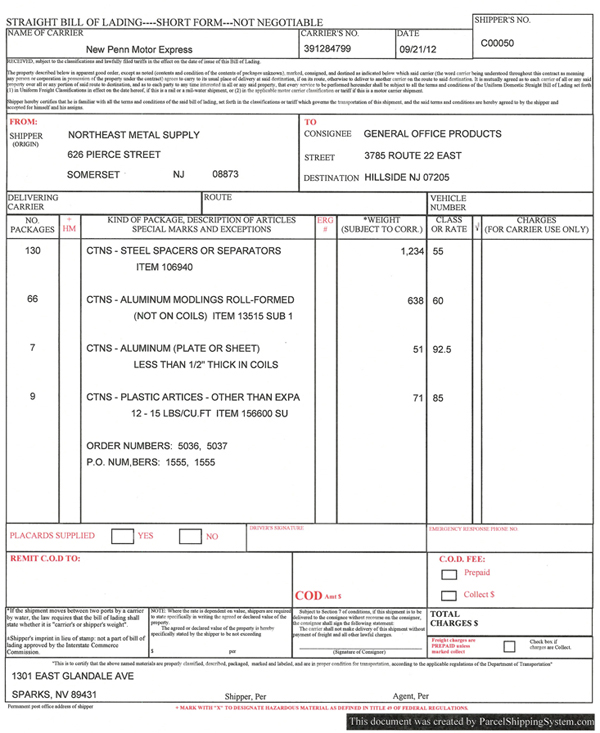

Part # 10128 - Bill of Lading Form - HP Laser

This will print a Bill of Lading on any HP or compatible laser printer. The format is the same as standard Rapid Forms bills of lading, thus eliminating the need for pre-printed forms. The program that generates the Bill of Lading is user modifiable, so the form can be customized to your needs.

|

|

Part # 10122 - LTL Carrier Rate Converter. Convert LTL rate spreadsheets into PSS format

This allows you to convert into PSS format LTL carrier freight rates for shipments to any location in the U.S. and Canada. All that is needed to convert a carrier's freight rates are comma-delimited (.csv) rate spreadsheets in a simple format defined in the PSS Documentation. One spreadsheet is needed for each ship from location and rate class, and the spreadsheets can either be generated by your carriers' rating software or supplied by your carriers. In addition, this feature program can also be used to convert LTL carrier time-in-transit files when supplied by your carriers in a format defined in the PSS Documentation. |

|

Part # 10014 - Level II Interface. This facilitates the connection between PSS and your database

PSS uses this interface, which includes a user-modifiable program, to allow direct access to and from your data files. Shipping information such as the consignee’s name, address, and method of shipment can be retrieved from your production system (ex. customer or order files). The same interface is used to allow you to update your production system with the PSS shipping information (ex. update your invoice with the freight charge and date shipped). There are various times throughout the processing of shipments that PSS will turn control over to the interface program. These “hooks” allow you to customize and automate the way PSS interacts with your users.

* A skeleton program is provided and must be customized for your application software before it can be used. |

|

Part # 10001 - Bar Code Module. Scan a bar code rather than entering the order # for a shipment

For increased speed and accuracy, PSS can interpret one scanned bar code from your document (ex. picking ticket, order form) to obtain information that would otherwise have to be entered in four different places (company #, invoice / order / pick-slip #, shipment #, and box #). This provides PSS with the information it needs to identify the shipment and proceed directly into the box processing stage. The included user-modifiable program reduces the likelihood that you will need to make any changes to your bar code. |

|

Part # 10069 - Alternate Party Billing. Allows Collect and 3rd Party billing

This feature allows you to process collect or third party billed shipments. All necessary information (customer account numbers, phone numbers, etc.) are captured from your existing database via the Level II Interface. Information for alternate party billed shipments can be printed on your bills of lading if you so choose. |

|

Part # 10012 - Optional Handling Charge. Add a user-defined handling fee per box or shipment

This feature gives you the ability to automatically add a handling charge in your shipping charges. The handling charge can be set up by parcel or by order and can be overridden by the operator if needed (and if you allow it). The included user-modifiable program enables you to make even more handling charge decisions automatically when the shipment is actually being processed. For example, you can base the handling charge on the customer or order total. |

|

Part # 10077 - Ship to Database. Create a database of non-customer names, addresses and ship via

This provides for the entry and maintenance of a stand-alone ship-to database that is integrated with the PSS rating & packing screens. When shipping a parcel that does not have a customer order associated with it (manual entry), this feature will save time and eliminate errors. By using “S” as an order number, PSS will bring the user into the ship-to database program. The ship-to can be cross-referenced by entering part of the name or filed as a new ship-to for future re-use. |

|

Part # 10005 - Picker Identification. Create codes for pickers and assign them to each box

You can monitor the employees involved with the shipping process by assigning them identifying codes. PSS will then prompt for the Picker Code to define the employee who picked the goods for a particular package or shipment. |

|

Part # 10006 - Packer Identification. Create codes for packers and assign them to each box

You can monitor the employees involved with the shipping process by assigning them identifying codes. PSS will then prompt for the Packer Code to define the employee who picked the goods for a particular package or shipment. |

|

Part # 10007 - Shipper Identification. Create codes for shippers and assign them to each box

You can monitor the employees involved with the shipping process by assigning them identifying codes. PSS will then prompt for the Shipper Code to define the employee who picked the goods for a particular package or shipment. |

|

Part # 10079 - Zip Code Verification. Insure correct zip codes and that cities and states match

This software will verify that the zip code used in a shipment is valid and that it matches the city and state entered. If PSS senses a mismatch or invalid zip code, the user will be warned and allowed to easily correct the data. Included with this option is a data base which can be used by your other software applications and which contains the cities, preferred city (if more then one) and state for more then 42,000 zip codes in the continental US, Alaska, Hawaii and Puerto Rico.

* Must subscribe to the ZIP code maintenance service. |

|

Part # 10041 - External Rating Screen Access. Run the PSS shipping station from a user application

This allows the PSS Shipment Rating Station screen to be called by any user-written application. For example, this feature can be integrated with your packing process so that package rating and labeling can immediately follow it or it can be used by customer service to allow operators to check the status of a given order. This relieves the user of the necessity of writing a shipping inquiry screen and prevents operators from having to log off and onto PSS to check the shipping data. Included with this are the parameters for calling a subroutine that will call the PSS Rating Screen and then return control to the calling program. |

|

Part # 10043 - User Rating Routine. Calculate shipping charges from a user application

This provides you with the ability to calculate the complete shipping charges for a particular shipment from any user-written application. For example, you can use this routine with your order entry process to estimate freight charges for quoting customers. Insurance, COD’s, and any other accessorial services can also be included in the rating process. You simply call the Rating Routine by using the included parameters and the rating results are returned for you to use or display. There is also a rate quoting screen provided that allows you to quote freight charges without having to implement any subroutine calling.

* No Rating Station License Required. |

|

Part # 10010 - Ship With Order Goods. Ship components of multiple orders in the same package

This software, also known as SWOG, allows users to link together shipments for different orders to the same customer on a given day. When shipments for different orders are packed in the same boxes, they are linked by both the order and carrier tracking numbers, and when either one is entered in the Rating Station a display will indicate what was shipped together. Billable freight charges can be allocated to different orders based on value or weight (if known), evenly based on the number of packages or any other business rules you choose to apply.

* Requires modifications to the Level II Interface program to verify that all shipments are to the same customer and address and to write tracking numbers, freight charges and other information back to the linked orders. |

|